I. INTRODUCTION

The lack of simulated industrial processes in virtual environments has created limitations in knowledge; currently, the integration of virtual reality technology in training systems for different methods has marked the way to success in industrial automation, allowing the use of virtual reality environments. Virtualis like means of training. Simulation in a virtual environment will enable operators to place difficult-to-access and control scenarios into real development scenarios, resulting in higher operational integrity. These new technologies allow users to create an interactive environment equipped with images of scenes and simulations, which facilitates the generation of virtual modules to train students and professionals capable of performing correctly as if they had been trained in a natural environment. Virtual training aims to provide an attractive and realistic tool to facilitate interaction between tools, systems, and processes in a secure environment. The present work is divided into three sections, the first being the theoretical foundation. The steps that were followed to implement the virtual environment are detailed, and finally, we proceed to the analysis of the results and conclusions.

II. DEVELOPMENT

In its beginnings, virtual reality was focused on video games, but technological advances have allowed it to focus on industry, education, and even medicine 1,2. The low cost of implementation, time savings, and low exposure to unnecessary risks have made Virtual Reality (VR) the number one tool in industrial education and training in recent years 3.

Virtual reality aims to move the real-world user to a high degree of immersion. It is necessary to take into account that there are two different types of virtual reality i) non-immersive VR, which is transmitted through monitors with 3D or 2D graphics without the use of external elements, and ii) semi-immersive VR, which combines virtual scenarios with the real world. This type of VR occupies devices such as projectors and high- performance computer systems 4,5. This digital tool has a wide range of possibilities in terms of its use, applied from the field of video games through medicine and becoming a low-cost option within the industry. Two powerful graphics engines are used to develop virtual reality 6.

Today, conventional teaching media are most often complemented by 3D virtual reality systems, given their educational potential 7. This is because virtual reality systems, compared to traditional teaching and other computer applications for didactic purposes, provide the user with a three-dimensional visual environment, highly interactive and very close to reality; All this through two key components: immersion and interaction 8. Currently, operators and workers in the industry can use technological tools to train themselves in their processes. The management and visualization of the elements of the process were in charge of an augmented reality application that was developed taking as reference the recognition of equipment through a smartphone to detect characteristic points of objects and image recognition, modeled in 3D through CAD software, and incorporating animations and mathematical modeling of industrial processes in a multiplatform. The results of this research allow users to manipulate and visualize elements of the process. It also helps the development of skills in the management of industrial processes that allows regulation without the need to perform additional actions in the physical process 9.

Virtual reality is a powerful tool for testing and evaluating new products and ideas in manufacturing processes, and the user has fully immersed themselves in exploratory simulation in rapid prototyping 10. Simulation games in software engineering are gaining interest among academic and professional researchers. Therefore, this paper describes an approach to creating educational simulation models derived from academic and industrial experiences 11. The development of an immersive 3D virtual reality platform that emulates the environment and operations of pipe pig cleaning (PPC) launch and reception traps was developed to reinforce the training of operators in the oil industry. To carry out this research, equipment manuals, procedures, technical specifications, photographs, P&IDs had to be compiled, and from this information, 3D digital plans (CAD) were modeled; and at the end of the process, with the help of the 3D Unity graphics engine, the virtualization of elements that are part of this process was carried out 12.

The control of electrical substations is being developed through a virtual environment. The research verifies that each 3D electrical substation is integrated into the monitoring center for data acquisition and control of an honest electric company 13. The researchers used a virtual environment to develop a process control for the cascade control system. The virtual environment provides realism and transparency in the process when its monitoring and control are carried out. According to these researchers, It is also used to develop student learning. 14. Through the teleoperation scheme, the operator is immersed in an augmented reality environment, which allows him to execute tasks aimed at 3D modeling in remote environments. 15. Robot animation in virtual reality environments is based on mechanical principles and the control unit, which allows simulations of movements in an established environment 16.

For the training on the operation of the pumping station and fire system, the following regulations were used:

NEC-SE-AC. - Corresponds to the design of structures.

Standard CO10.7 - 602.- Defines the requirements for the design of a water pumping station. NTE INEN 440:1984. - Sets the pipe identification color code.

NTE INEN-ISO 3864-1:2013. - Defines the requirements of colors, signs, and safety symbols.

NEC-HS-CI. - Focuses on the minimum requirements for fire protection in industrial occupations.

ISA S88 STANDARD. Defines the requirements for building piping and instrumentation (P&ID) diagrams.

III. METHODOLOGY

A. System Structure

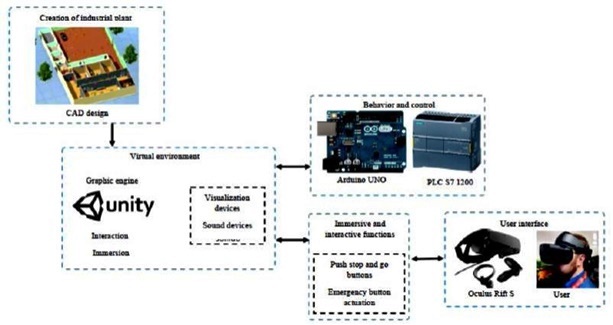

This paper presents the development of an application in an interactive virtual environment for the training of operators of pumping stations and fire systems. With this application, exercises can be carried out in managing fire emergencies in industrial plants. Once an infrastructure for the water pumping station and fire system is created, each component is worked out in DWG format individually and assembled until the preliminary design is obtained. Next, it is imported into the Unity 3D graphics engine in FBX format, where the initial setup is improved, adding animations, sounds, and textures for the realistic simulation of the process control. See Figure 1.

The Leap Motion gesture controller and the S HMD are considered in the input stage. The HMD can change the viewing angle and track users' movements. Leap Motion handles hand recognition to be able to use them within the environment and thus access various functions of it. Industrial variables such as temperature and pressure are functional. They are not real. These industrial variables are the basis for generating environmental emergencies since exceeding them will cause a dangerous event to occur in the shortest possible time. Industrial variables in the virtual plant have different behavior depending on the data sent from the plant event manager. When the operating ranges of plant processes are exceeded, there will be industrial emergencies. The communication between Unity 3D and Arduino UNO is implemented through an S7 1200 PLC, which allows real-time communication between the two programs used to send data unidirectionally or bidirectionally, thus obtaining control of plant events externally, through a computer or remotely through an Ethernet network, Wi-Fi or internet.

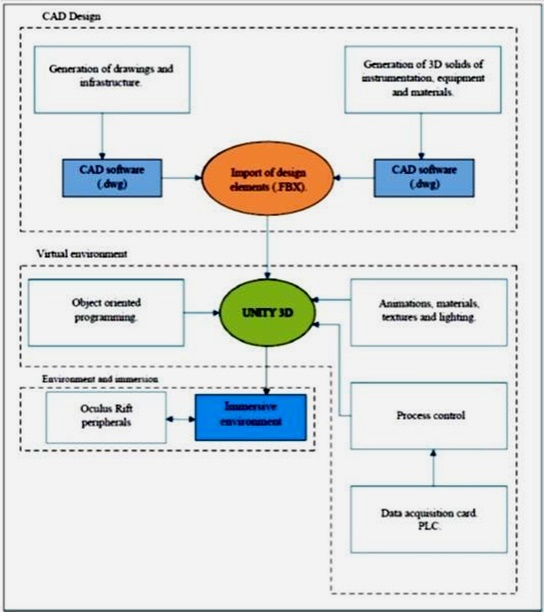

B. Virtual environment

The finished product storage area of an industrial plant that produces plastic and paper containers was chosen as the setting. The design features of a virtual reality training system should be as close as possible to the components of the actual procedure. There are two main parts to creating the virtual process environment. The structure, piping, and some equipment are designed in the software and then exported in a readable format. Later in Unity3D, instruments, equipment, and accessories required in FBX or OBJ format are imported, problems with the position and scale of the objects are corrected, and rotation points of the things that need it are configured. Figure 2 shows the diagram describing the process used to deploy the VR application.

C. Preliminary CAD design

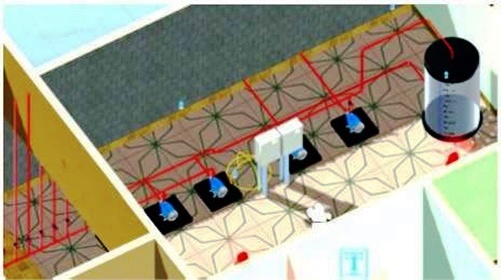

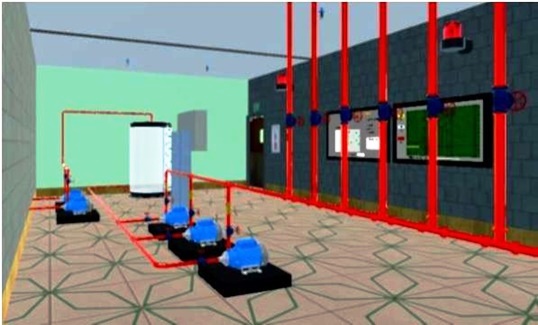

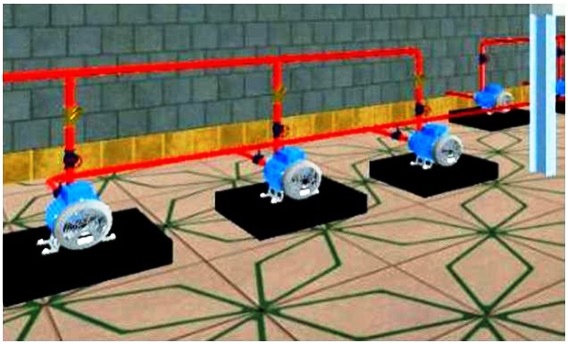

This design stage presents the creation and interconnection of instruments and equipment using CAD tools such as AutoCAD Plant 3D, a program oriented to the design of industrial plants, which allows to generate, modify and interconnect the components of the piping and instrumentation diagram using three-dimensional and realistic objects, as shown in Figures 3 and 4. The digitized environment in which the user will be immersed to train in managing pumping stations for fire-fighting systems requires the highest level of detail and realism possible to obtain high-impact exercise.

D. Design in Unity3D

The design implemented in AutoCAD Plant 3D is imported in FBX format in Unity3D. It must be fully characterized, for which it is necessary to create the materials corresponding to each object and its subsequent assignment. Creating a place where the plant is located is critical to improving the level of detail. Process functions are not affected by these details but provide more convenience to the user (Figure 5).

E. Incorporation of safety signage.

Safety signs were incorporated since everyone must know and comply with safety standards to eradicate occupational accidents. The NTE INEN-ISO 3864-1:2013 standard refers to safety signs and symbols at different plant points. These signs are already pre-designed in the CAD software, and within Unity3D, colors and textures are assigned for better visualization (Figures 6 and 7).

F. Implementation of sound, HMI, Fire, and Water Particle Systems.

It is necessary to insert sounds and effects to give a realistic impression to the user. The pumps are switched on and off using a script. The Audio Source component, which contains the audio control imported into the simulation, can be used to modify the audio volume and effects (Figure 8).

The dashboard displays the PI&D control variables of the tank level, the status of the pumps, the fire alert in each plant zone, and the trend curves of the tank control variables. This panel was configured by creating a Canvas object, a canvas that comes in unity3D tools, in which buttons, panels for images, texts, and sliders are added- Finally, colors are assigned to form a control panel of them (Figure 9).

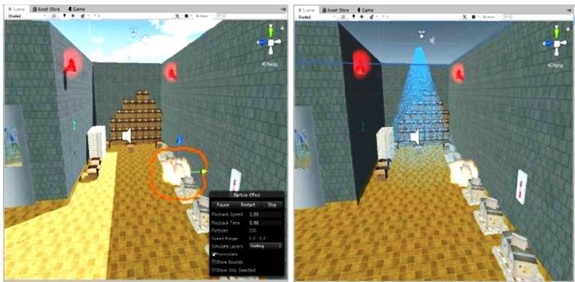

For more realistic animation, effects and textures are added to particle systems, which are created to mimic the effects of water and fire. The results and the particle system can be entered in the Game Object tab obtaining a new object which controls the speed, size, texture, quantity, and consequences as required, a new script is created, and the particle systems are controlled (Figure 10).

G. Student settings

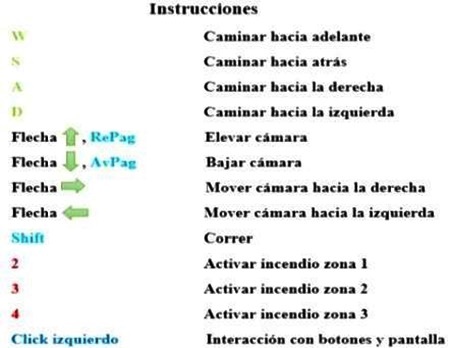

It is possible to interact with characters who perform tasks within the application. The student will observe through a virtual camera in an invisible capsule component that interacts with the environment, which can be controlled by the navigation keys of the computer to move and the mouse to change the angle of view or by using virtual reality glasses. To control the functions of the student, it is necessary to create a script that can be used. A script containing the code is added for its control on the Stage so that it does not float (Figures 11, 12, and 13).

IV. RESULTS

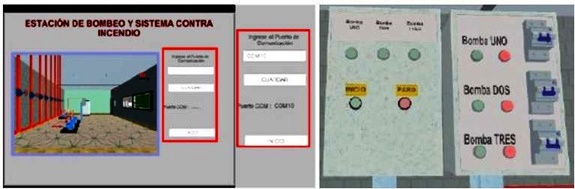

The objective of the Virtual Reality application is to show a realistic system of a pumping station and a fire system for the interaction of the student in the first person. The data acquisition card can communicate with the COM port on the control panel to control the system. To start the system, press the start button on the first control panel and select the tank level using the SetPoint controller (Figure 14).

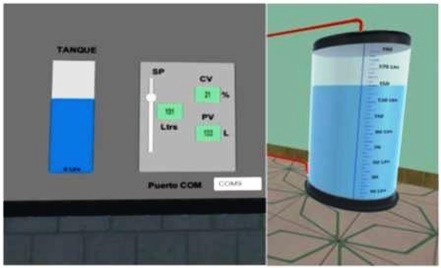

In the environment, you can experience the operation of a water pumping station. In this part of the system, the student or operator can interact with the screen to select the level of the tank that a P&ID controls; this is done by entering the value of the Setpoint. A transparent material is used to observe the tank level and compare it with the group at the Setpoint. For this analysis, the value of 151 liters in the Setpoint was selected, which can vary from a minimum of 0 liters to a maximum of 200 liters. When selecting the Setpoint, the P&ID developed for level control will reflect the same value chosen in the tank, as shown in Figure 15.

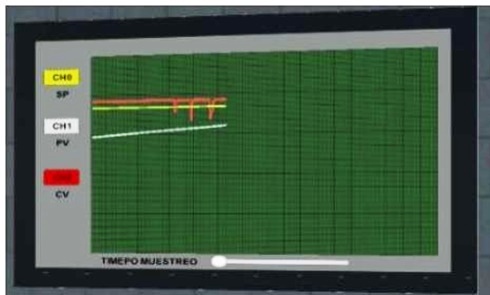

The P&ID control was performed to control the liquid level in the tank, maintaining a constant water level and compensating for this consumption, and always keeping it at the desired level, which is monitored from the control panel that shows us the response curves of the variables that act. This control communicated satisfactorily between the Unity3D graphics engine and the PLC sending signals from 0 to 5 V through the data acquisition card that internally conditions this voltage signal at the output and the input. The response curves of the tank level control are shown below in Figure 15.

This figure shows the curve trends in response to the P&ID control. The yellow curve represents the reference point; the white Process Value rises to reach the required level, and the Control Value represented by the red color is at maximum; during the process, this will decrease as the Process Value reaches the desired point.

Finally, a fire can be simulated in Zone 1 of the plant, where the sprinklers react to the fire by activating the fire alarm, thus starting the water sprinklers over the affected area. But since in industrial processes, equipment, instruments, materials, and systems can fail at any time, it is also possible to simulate the failure of the main pump of the fire system and have any of the other two pumps connected to the system work. In this case, a fire occurs in zone 1, as the water pumping system pumps one comes into operation, as shown in Figure 16.

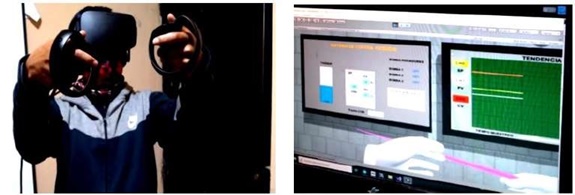

Figure 17 shows the Touch controllers for the operator to perform maneuvers in the immersive virtual environment.

Figure 18 shows the user operating the water storage tank and sprinkler system using the Oculus Rift S virtual reality goggles and Touch controllers.

Figure 19 shows the user interacting on the fire system pump control boards using the Oculus Rift S virtual reality goggles and Touch controllers.

V. CONCLUSIONS

An immersive virtual reality application has been implemented for the training and education of operators and students in the operation of a pumping station and a fire system that allowed the selection of equipment, materials, and components necessary for the design of the immersive environment.

For 3D modeling, Sketchup CAD software proved optimal for creating the preliminary design of the pumping station and fire system, performing 80% of the three-dimensional structure of equipment, fittings, piping, and instruments essential for the development of the environment.

The Unity 3D graphics engine comprises a wide range of functions that help complete the 20% that was missing in the design of the industrial plant and make the immersive virtual environment resemble reality; this software allowed to give animations, movements, and control that allowed training in the operation of the water pumping system and fire system.

Integrating the Oculus Rift S device into Unity3D allows the user to control the system's operation 100% by interacting virtually, also through the external PLC S7 300 controller consisting of 3 modules with inputs. These digital and analog outputs correctly control the system by sending and receiving electrical voltage signals ranging from 0 to 5V.

uBio

uBio